XR®

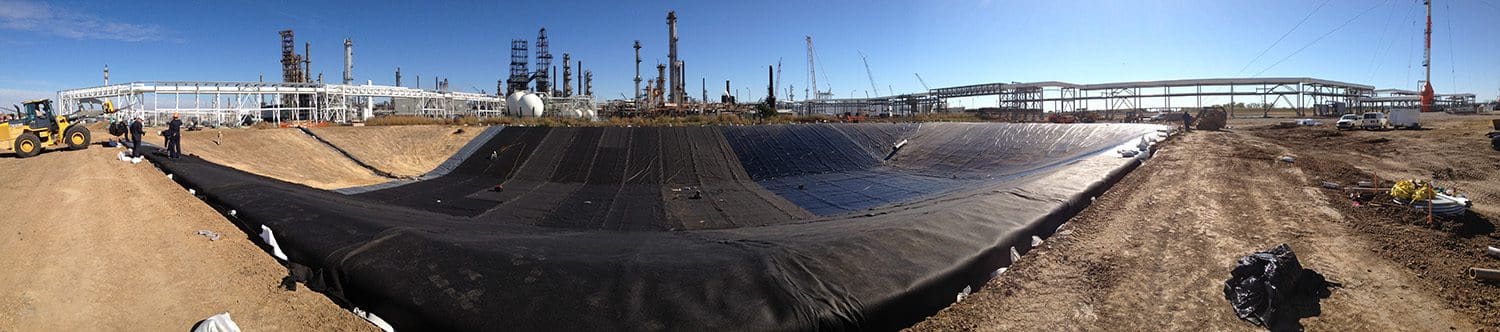

Compared to other membrane materials, XR® membranes are exceptionally strong, with very high puncture and tear resistance. Its reinforced, multi-layered design provides maximum strength-to-weight ratios and flexibility for ease of handling. The ethylene interpolymer alloy (EIA) coatings make the material resilient to environmental stress cracking, high loads, and temperature fluctuations.

XR® products come in three grades: XR®-5, XR®-3, and XR®-PW (Potable Water).

XR®-5 geomembranes provide over 300% higher puncture strength vs. twice as thick 60 mil HDPE and over 200% better tensile strength. XR®-5 geomembranes also provide 22 times lower thermal expansion and contraction compared to HDPE.

Advantages of XR® Liners

- Excellent chemical resistance

- Hydrocarbon resistance

- Low thermal expansion/contraction

- UV stability

- Very high-strength material with superior seam strength

- Large panel fabrication requiring less field seaming during installation

Applications for XR® Liners

- Military vehicle wash facilities

- Ocean reclamation

- Methane bladders

- Dike and slope facings

- Buried tank vault liners

- Tank farms

- Jet fuel storage facilities

- Heap leach facilities

- Railroad road fueling facilities

- Transformer oil secondary containment basins

- Secondary containment hydrocarbon applications

- Floating covers

- Specialty products and accessories

Contact LCSI today for all your containment needs.